Engineering Drawings

With proper, detailed manufacturing drawings you can be sure that all the parts will fit together as intended.

The key to this is to set the right tolerances for the manufacturing processes used. To get this right a the outset of your project our engineers will agree a working tolerance scheme based on the manufacturing facilities available.

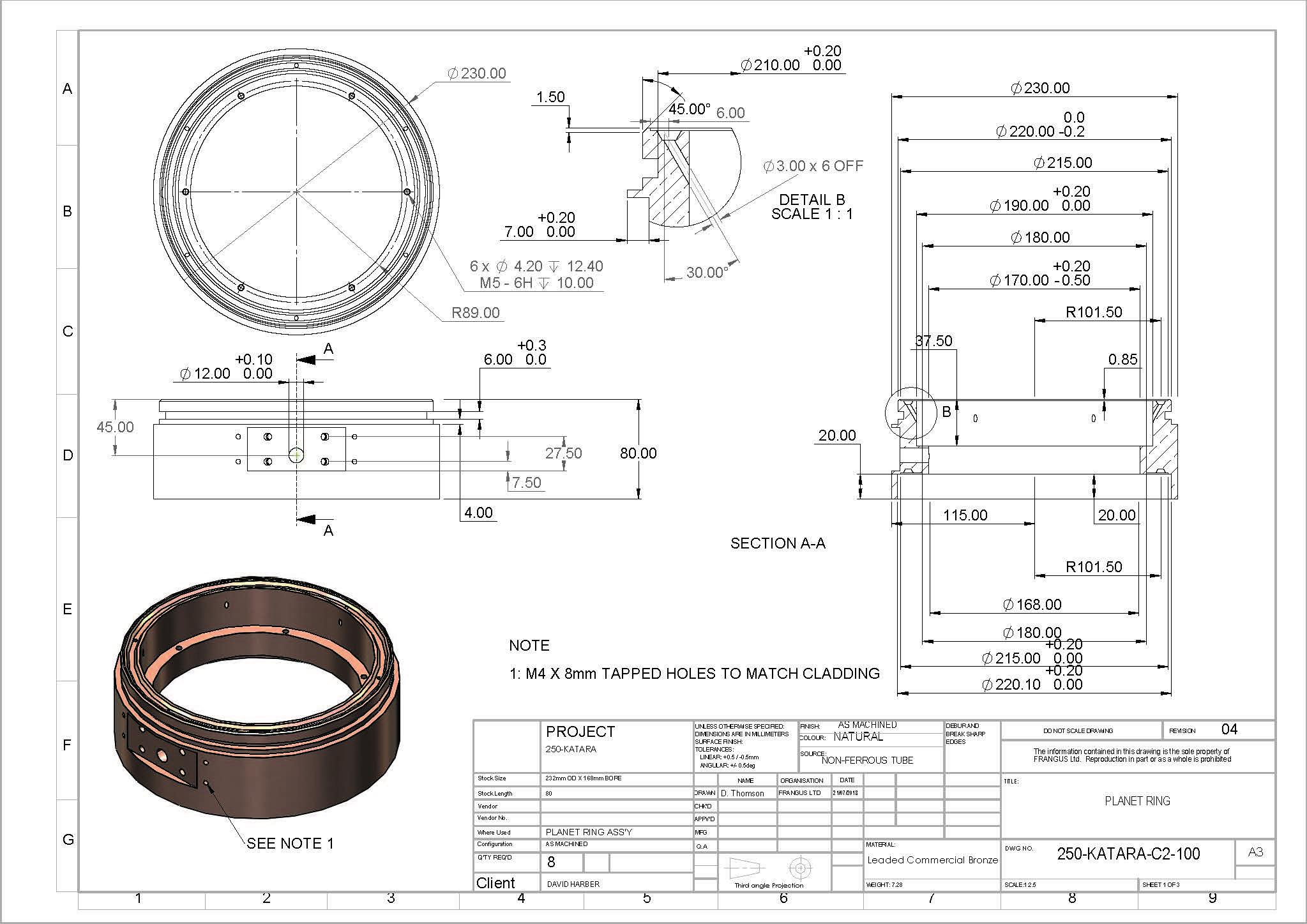

Part Drawings

A part drawing must provide all the information necessary to manufacture the part and to ensure that the part will fit.

The key to this is to set the right tolerances for the manufacturing processes used. To get this right a the outset of your project our engineers will agree a working tolerance scheme based on the manufacturing facilities available.

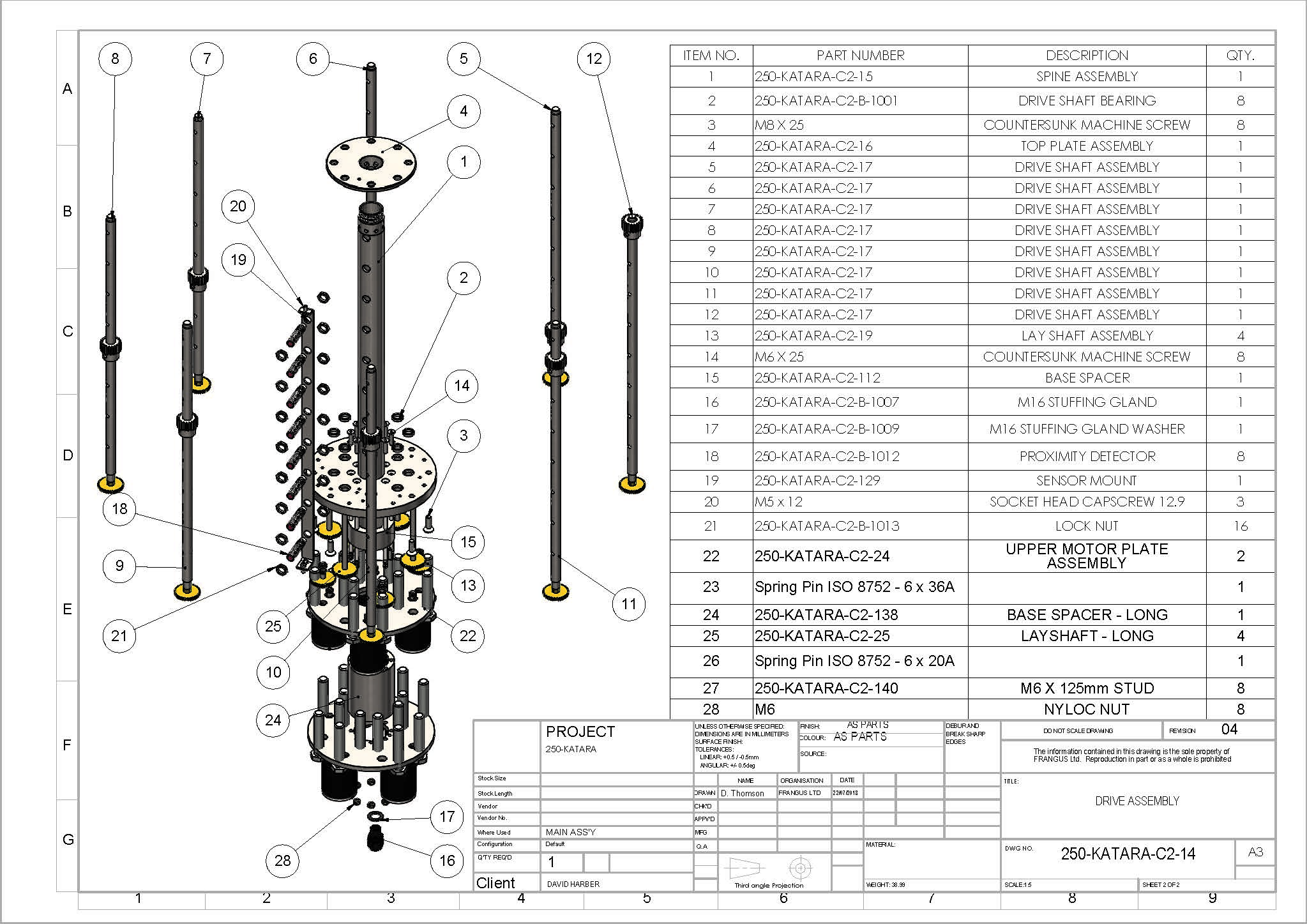

Assembly Drawings

Assembly drawings normally include a parts list and details of any assembly and finishing processes to be applied to the assembly.

It should be possible to clearly identify all the parts used in an assembly and how they fit together from the assembly drawing. However, for complex assemblies it is sometimes better to limit the assembly drawing to include the parts and their quantities and document the assembly procedure in a technical document.

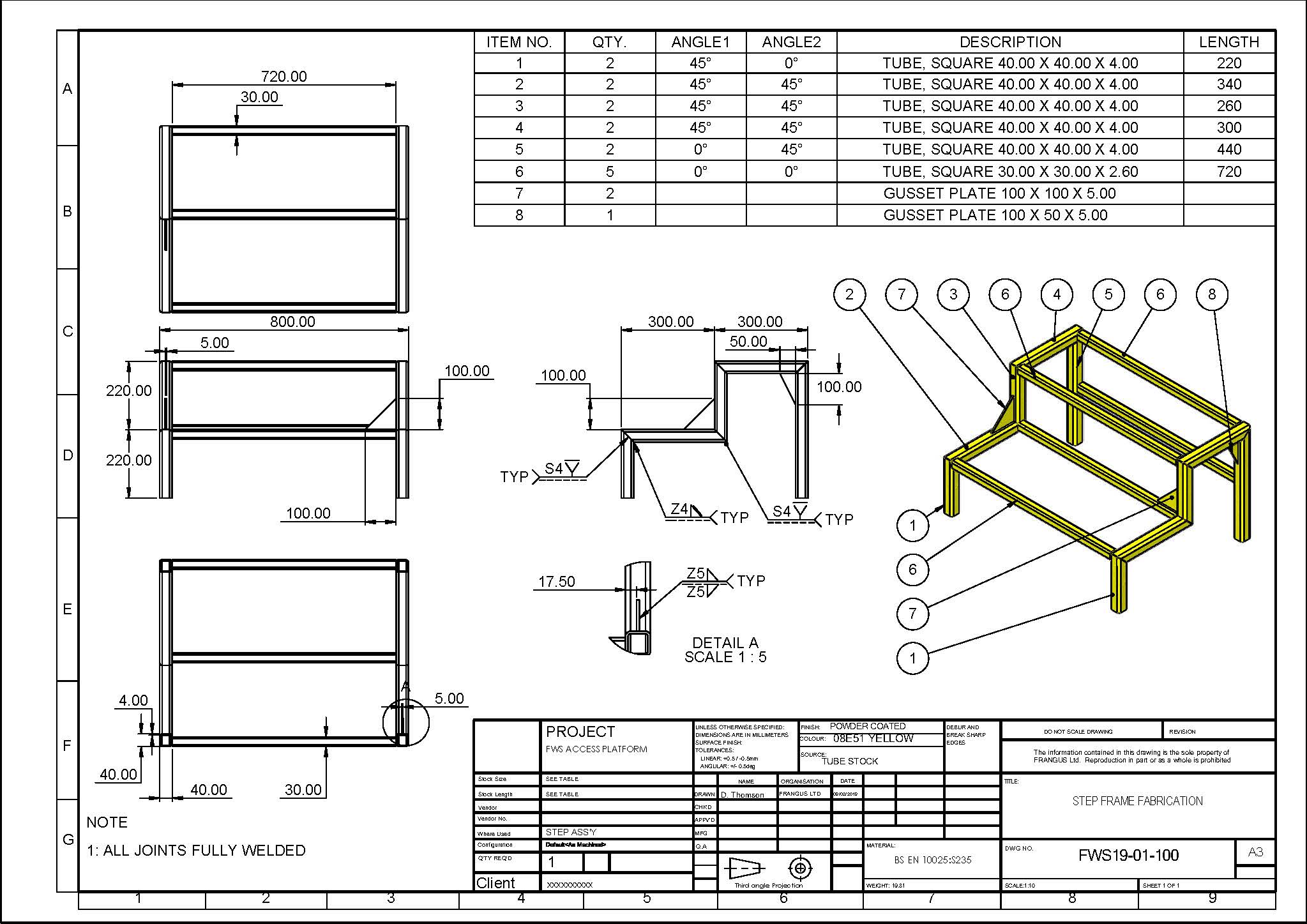

Weldment Drawings

Weldment drawings, which include cutting lists and weld data help to ensure that welded structures are completed correctly.

Parts Drawings

Drawings created directly from the parts models ensure that the design intent is fully captured.

All the dimensions and metadata stored within the part model are automatically transferred to the drawing sheet.

Assembly Drawings

An assembly drawing lists all the parts requied to complete the assembly and details any finishing operations to be applied.

See also our Technical Documentation page for how the model can also be used to create assembly instructions and repair manuals.

Weldment Drawings

Fully detailed manufacturing drawings of welded assemblies including cut lists, weld details and key dimensions to ensure that the final assembly meets the design requirements.